- Services

Road measurements

Road bearing capacity (FWD)

Roughness (IRI & IRI4)

Rut Depth Measurements

Pavement Skid Resistance Measurements

Pavement thermal measurements (TGS)

ITS & road information systems

Road and Traffic Cameras

Road Weather and Road Weather Stations

Traffic counting

Variable Message Signs

Weigh-in-motion

- Trainings

- Contact

ENG

- Services

Road measurements

Road bearing capacity (FWD)

Roughness (IRI & IRI4)

Rut Depth Measurements

Pavement Skid Resistance Measurements

Pavement thermal measurements (TGS)

ITS & road information systems

Road and Traffic Cameras

Road Weather and Road Weather Stations

Traffic counting

Variable Message Signs

Weigh-in-motion

- Trainings

- Contact

ENG

SERVICES

Road information center

Consultations and Studies

- Expert Assessments

- Construction Supervision

Road Information Systems

Testing and Measurement

- Laboratory Tests

- Road measurements

- Ground Penetrating Radar

- Pavement Skid Resistance Measurements

- Residual voids content (GPR)

- Transverse profile & cross slope

- Rut Depth Measurements

- Roughness (IRI & IRI4)

- 3D Road Imaging System

- Pavement thermal measurements (TGS)

- Pavement layer thickness (induction method)

- Assessment and analysis of the condition of bridges

- ELTRIP road distance and friction meters

- Ground Penetrating Radar

Certification Department

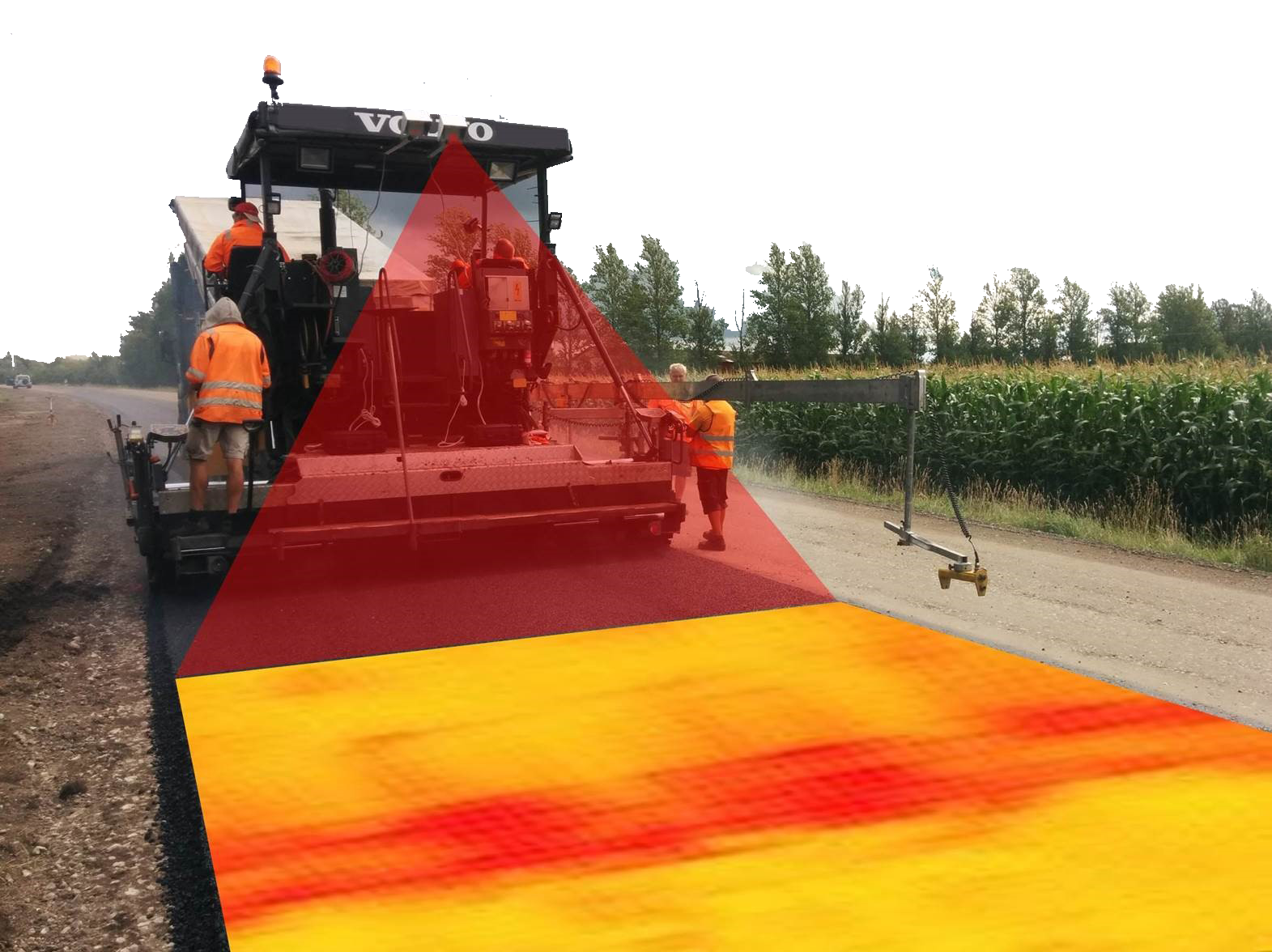

Pavement thermal measurements (TGS)

The quality of the installation of asphalt pavements has increased year by year, but even today, the quality is often stuck in the details – did the mix load cool down during transport to the site, did the asphalt mix stop due to a technical failure, etc. There are less and less situations where the entire daily production is of poor quality. At the same time, individual or regularly occurring defects spoil the quality almost as much, because even if only 5% of the road surface has deteriorated, the entire road surface still needs to be repaired. Therefore, good quality is characterized by the uniformity of the asphalt pavement.

We have been dealing with the topic of measuring the uniformity of asphalt pavement installation since 2014. To measure the installation temperature of road surfaces, we developed the TGS Pavement device, which allows you to get an accurate overview of the temperature uniformity of the asphalt mixture being laid in real time and save all the data for later analysis. An online environment has been created to display the visualized measurement data and make extracts from the measurement data, through which the work process can be monitored by the users designated by the work orderer.

TGS Pavement is easy to handle, compatible with all paver makes and models, and provides real-time feedback on pavement installation quality to the entire installation team over the web. For the road owner, the device offers accurate documentation of work quality. Together with an appropriate bonus system, TGS ensures a high level of motivation for the entire team involved in laying to implement various measures to achieve the best quality. At the same time, the construction team has complete freedom of choice for the implementation of measures.

Real-time feedback means an opportunity to prevent major problems and maximize the income of both the builder and the road user due to long-lasting coverage and a higher bonus.

The methodology is based on the respective methodologies of Finland and Sweden, which have been adapted to the conditions of Estonia.

TGS offers:

- compatibility with all spreaders

- compliance with the installation quality bonus measurement requirements established by the Road Administration

- real-time monitoring of the work process for all team members over the web

- visualization and analysis of measurement data in a web application

data download

The device meets the following criteria:

PROPERTY

VALUE

The accuracy of the measurement location (odometer and coordinate).

±0.5 m along the road

Measurement width

> 5 m

Longitudinal interval (measurements per meter)

≥ 2

Transverse interval

≤ 0.3 m

Temperature information with location and time stamp

YES

Edge removal width

≤ 0.3 m

Measuring distance from the rear edge of the spreader

< 5 m

Real-time monitoring of installation temperatures

YES

Temperature measurement range

(25-175) o C

Accuracy of the device in temperature measurement

± 2%

Recording of thermal images/thermal carpet

YES

Spreader movement speed

YES

Get in touch

Pavement thermal measurements (TGS)

Road information center

Consultations and Studies

- Expert Assessments

- Construction Supervision

Road Information Systems

Testing and Measurement

- Laboratory Tests

- Road measurements

- Ground Penetrating Radar

- Pavement Skid Resistance Measurements

- Residual voids content (GPR)

- Transverse profile & cross slope

- Rut Depth Measurements

- Roughness (IRI & IRI4)

- 3D Road Imaging System

- Pavement thermal measurements (TGS)

- Pavement layer thickness (induction method)

- Assessment and analysis of the condition of bridges

- ELTRIP road distance and friction meters

- Ground Penetrating Radar

Certification Department

Seda veebilehte külastades ja kasutades nõustud sellega, et AS Teede Tehnokeskus kasutab küpsiseid. Nõustun REJECTManage consent

Seda veebilehte külastades ja kasutades nõustud sellega, et AS Teede Tehnokeskus kasutab küpsiseid. Nõustun REJECTManage consentPrivacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.